Get your copy of Dr. Matthew Litione’s,

Five Essential Steps for Choosing the Right Control Panel

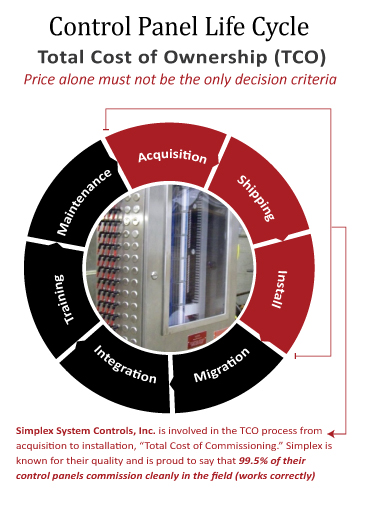

In a helpful article, Dr. Mathew Liotine, Associate Professor of Information and Decision Sciences at the University of Illinois at Chicago, reviews the relationship between control panel quality and the total cost of ownership.

Dr. Liotine elaborates that calculating the total cost of ownership requires that you consider the entire product lifecycle – from commissioning to disposal.

The total cost of ownership includes costs associated with maintenance, repair and loss expectancy. Panels of lower quality may require frequent repair. There is also the very real possibility of loss due to work stoppage.

Please Provide the Following Information:

Receive Your Copy of “Five Essential Steps for Choosing the Right Control Panel”

Articles of Interest

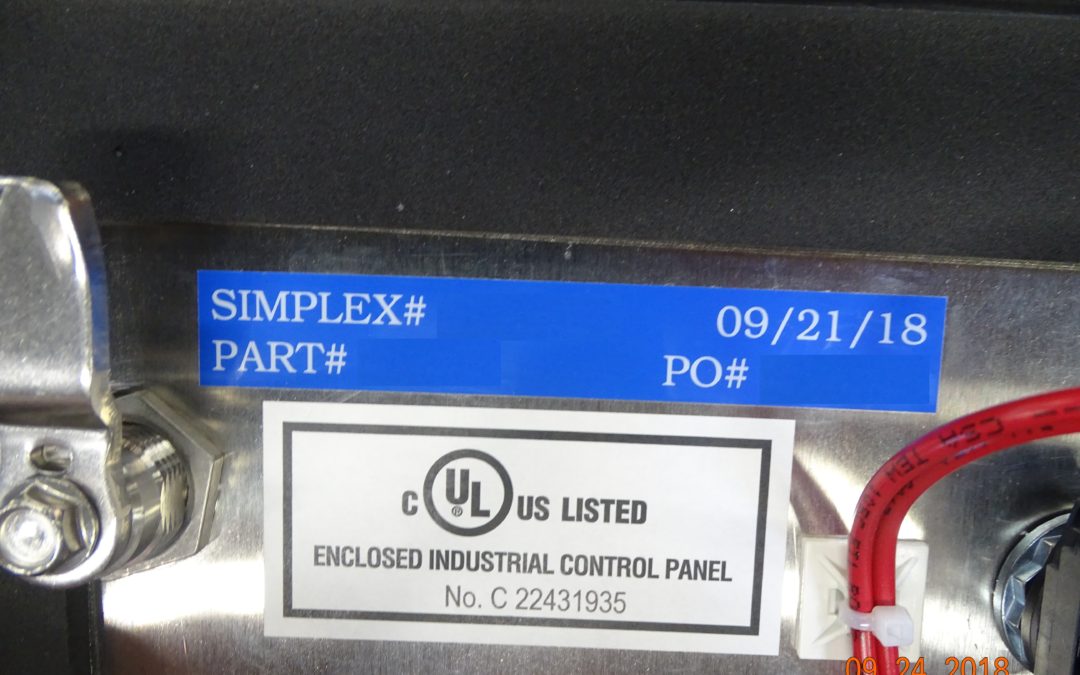

UL Certification for Control Panels: What it is and Why You (Probably) Need It

UL Certification for Control Panels: What it is and Why You (Probably) Need It … Almost all of us have at one time or another, seen UL Listed labels (marks) on the bottom of toasters, appliances, lights, and many other consumer and industrial products and devices. Thanks to these labels, Underwriters Laboratories (UL) enjoys broad name recognition. Yet most of us are probably unaware of exactly what UL is, why it’s important, and how those ubiquitous labels came to be.

How Automation Improves Control Panel Assembly

How Automation Improves Control Panel Assembly, “The story of modern factory automation begins in 1782 when Oliver Evans (1755-1819),” Simplex PWA600

The Power of Continuous Improvement

If You’re Not Improving, You’re Falling Behind

Recently, Kurt Sundberg, President of Simplex, recounted that a mentor would tell him that “if you’re not improving, you’re falling behind.” He’s lived by those words and has stayed focused on continuous improvement.

Kurt described also being influenced by The Toyota Way. In fact, the Simplex management team read Liker’s book and were tasked to reflect on how it may apply to their operation. Kurt related that, “Internally, we wanted to look deeper at things we never really looked at before. We had an interest in lean manufacturing and continuous improvement and what that looked like for us. That led us to the Toyota Way.”