Almost all of us have at one time or another, seen UL Listed labels (marks) on the bottom of toasters, appliances, lights, and many other consumer and industrial products and devices. Thanks to these labels, Underwriters Laboratories (UL) enjoys broad name recognition. Yet most of us are probably unaware of exactly what UL is, why it’s important, and how those ubiquitous labels came to be.

The story begins in Chicago

In 1893 the world was amazed by the many wonders on display at the World’s Columbian Exposition in Chicago.

The first Ferris wheel debuted at the Exposition as well as a host of new electric inventions – the electric sidewalk, a “fax” machine that sent pictures over telegraph lines, irons, sewing machines, laundry machines, and moving pictures courtesy of Thomas Edison’s Kinetoscope.

For many of the 27 million attendees however, Edison’s electric lightbulb was the highlight of the fair. Although Edison’s bulb was invented fourteen years earlier, the exposition was the first opportunity that most Americans had to see one in person.

In fact, it was the widespread and dazzling use of electric bulbs at the fair that led to the founding of Underwriter’s Laboratory (UL). UL’s founder, William Henry Merrill, Jr., a graduate of the Massachusetts Institute of Technology (MIT), was sent by his employer – the Boston Board of Fire Underwriters – to assess the risk of fire at the exposition.

While there, he saw the need for and proposed the creation of an electrical testing laboratory. The Chicago Underwriters Association and the Western Insurance Union provided funding to support his vision, paving the way for Merrill to establish the Underwriters Electrical Bureau in 1894.

Briefly known as the Electrical Bureau of the National Board of Fire Underwriters, by 1901 the name was changed to Underwriters Laboratory and the organization incorporated in Illinois.

Ironically, it was a tragedy several years after the exposition that spurred the growth of UL and the development of its well-known program of safety certifications.

The Iroquois Theater Fire

On Dec. 30, 1903, an over capacity crowd of almost 2,000 people (mostly women and children) packed into Chicago’s new Iroquois Theater to watch a matinee performance. Proclaimed “fireproof beyond all doubt” by the local fire inspector and a building commissioner just a few weeks earlier, an arc light ignited a backstage curtain and quickly spread throughout the theater.

Panic and chaos erupted in the theater. Sadly, numerous material, equipment, and building design flaws allowed the fire to surge out of control and prevented many theatregoers from being able to escape the flames. Within 15 minutes 602 people had perished.

The Iroquois Theater Fire was the deadliest single-building fire in United States history and sparked nationwide outrage. Not surprisingly, the tragedy led to increased attention on fire safety and calls for new standards and regulation.

UL stepped into the void and published its first Standard for Safety – “Tin Clad Fire Doors.” These types of doors were primarily used in public spaces such as warehouses, schools, and hospitals. And by 1906, UL had inaugurated its label service to test and certify individual products meeting defined safety standards.

The Present Day

Headquartered in Northbrook, Illinois, UL evolved over the years to become a global safety (nonprofit) organization with offices in 46 countries and a network of 64 laboratories and testing facilities.

The “label service” begun in 1906 grew along with the organization. UL branched from its roots in electrical and fire safety to cover broader safety issues including hazardous substances, water quality, food safety, performance testing, safety and compliance education, and environmental sustainability across a wide range of consumer and industrial products and industries.

In June 2022, UL revealed that it had reorganized into three organizations or brands – two nonprofit (UL Research Institutes, UL Standards & Engagement) and one commercial business (UL Solutions).

UL Solutions

UL Solutions is the entity that offers certifications for facilities, personnel, processes, products, and systems across a range of industries including automotive, construction, chemical, energy, utilities, healthcare, and industrial products and systems.

In terms of industrial products and systems, UL Solutions focuses its services on machinery and automation, instruments and controls, low and medium voltage distribution, manufacturing facilities, and Industry 4.0 cybersecurity.

Of most interest to Simplex and our customers, of course, is electrical control panels. But before diving into the details of control panel certification, let’s take a step back and ask a simple question – do you need safety certification for your control panels?

Do you need safety certification?

Panel safety and compliance is managed at both federal and local levels. Specifically, it is an Authority Having Jurisdiction (AHJ) that determines if you need certified panels for a specific application.

Most municipalities in which you do business will have codes or regulations that require electrical control panels to be certified by a Nationally Recognized Testing Laboratory (NRTL). Requirements can vary from jurisdiction to jurisdiction, so it is advisable for any company that sources control panels to clarify the requirements of the AHJs in which they operate.

Local jurisdictions are increasingly likely to require that industrial control panels be listed (certified) by a Nationally Recognized Testing Laboratory (NRTL). There are many reasons for this – including that the fact that is rare to find a local inspector who has the time to examine every component of every control panel.

What is a NRTL?

A NRTL is an independent third-party organization recognized by the Occupational Safety & Health Administration (OSHA) to provide evaluation, testing, and certification of products. All NRTLs conduct testing and certification based on nationally recognized safety standards.

UL Solutions is one of several NRTLs approved by OSHA for testing and certification. Others include CSA Group Testing and Certification Inc. (CSA), FM Approvals (FM), and MET Laboratories (MET).

In the United States, UL Solutions (né Underwriters Laboratories) just happens to be the oldest, largest, and best known NRTL. It is widely recognized and accepted by municipal inspection authorities in the United States and Canada. For this reason, a UL listing is typically the best way to facilitate and expedite the installation and approval process in most jurisdictions.

How to get your control panels listed

The easiest way to get your control panels UL listed is to have them labeled at the shop that manufactures them for you.

The UL Industrial Control Panel Shop Program (ICP Program) allows control panel manufacturers who custom-build or mass-produce panels to apply the UL Marks for the U.S. and Canada right at the factory.

The program allows flexibility for panel manufacturers, in that they can label mass-produced and custom-built panels without the need for UL to examine each design or panel.

The ICP Program ensures that a panel shop consistently produces panels that meet the necessary standards. Because a panel shop’s level of knowledge and quality control measures are important elements of ICP Program, training is required for panel shops that participate in the program:

Control panel manufacturers initially entering the Industrial Control Panel Shop Program are required to complete mandatory training on the UL 508A industrial control panels Standard and then maintain qualified staff knowledgeable of the requirements of the Standard.

What is 508A?

The UL standard applicable to most control panels is 508A. This is the UL Standard for Safety of the Construction of Industrial Control Panels and covers proper component selection/usage, calculation of short-circuit current ratings, enclosure environmental ratings, wiring, motor protection, safety markings, and conformance to the National Electrical Code (NEC) and Canadian Electrical Code (CEC).

These requirements cover industrial control panels intended for general industrial use, operating from a voltage of 1000 volts or less, where the ambient temperature does not exceed 40°C (104°F) maximum.

A note on hazardous locations

Some companies who source panels may need to meet other, specific UL standards. These can include 1203 (explosion-proof and dust-ignition-proof electrical equipment) and 698a (relating to hazardous locations).

The requirements found in UL 698A (Standard for Industrial Control Panels Relating to Hazardous (Classified) Locations) covers panels intended for installation and use in ordinary locations with intrinsically safe circuit extensions into Class I, II, and III, Division 1 and 2 hazardous (classified) locations.

The Standard for Explosion-Proof and Dust-Ignition-Proof Electrical Equipment for Use in Hazardous (Classified) Locations (UL 1203) covers panels that are designed to be explosion proof and dust-ignition proof for installation and use in hazardous (classified) locations.

Per OSHA, “hazardous locations” include those that are “classified depending on the properties of the flammable vapors, liquids or gases, or combustible dusts or fibers that may be present therein and the likelihood that a flammable or combustible concentration or quantity is present.”

The cost-effective solution to certify your panels

A UL listing (mark) helps the end user of a control panel satisfy AHJ regulatory requirements. UL listed industrial control panels are constructed and marked to facilitate installation.

If inclined, a company can take on the responsibility of certifying any or all the control panels that they source for customers. Even already installed panels can be certified on location by UL. To do so, however, requires a significant investment of both time and money. In most cases, it is simply more cost-effective to work with a trusted partner.

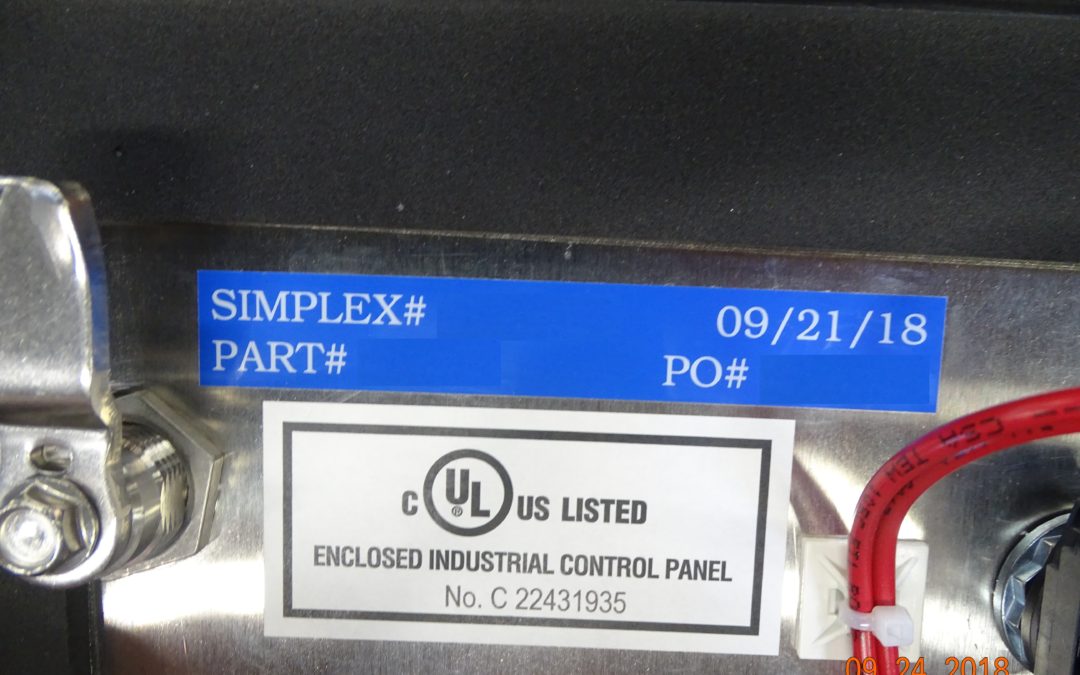

Look for a shop, such as Simplex, that participates in the UL Panel Shop Program. This means that UL has tested representative products manufactured by the shop and determined that they meet specific, defined requirements. These requirements are based on UL’s published and nationally recognized Standards for Safety.

As a UL Panel Shop, Simplex offers our customers panel certification under Standards 508A (general industrial use), 1203 (explosion-proof/dust-ignition-proof electrical equipment), and 698A (panels for hazardous locations).

The panel shop program requires that shops maintain qualified staff knowledgeable of the requirements of the standards. Each location must maintain at least one UL 508A qualified manufacturer technical representative (MTR) on staff who can effectively interpret and accurately apply the requirements of the UL 508A industrial control panels Standard.

Last year, Simplex project manager Van Williams successfully completed and passed the required UL Manufacturer Technical Representative (MTR) exam.

Dozens of companies rely on Simplex System Controls to meet customer demands for UL marked panels. Contact us for more information about our UL certification services, including associated costs, and the many other ways that we add value for our customers.

Manufacturers Simplex System Controls’ Blog is looking to hear from you.

Be next to share your story supporting innovation, quality, or integrity.

If you are an engineer, engineering firm, one of our vendors, or manufacturer and want to collaborate on an article or have an industry story to share, contact our sales and marketing team. Also, reach out if you have strong opinions on this article.

Contact:

Ron Rytlewski, [email protected]

(630) 766-8401